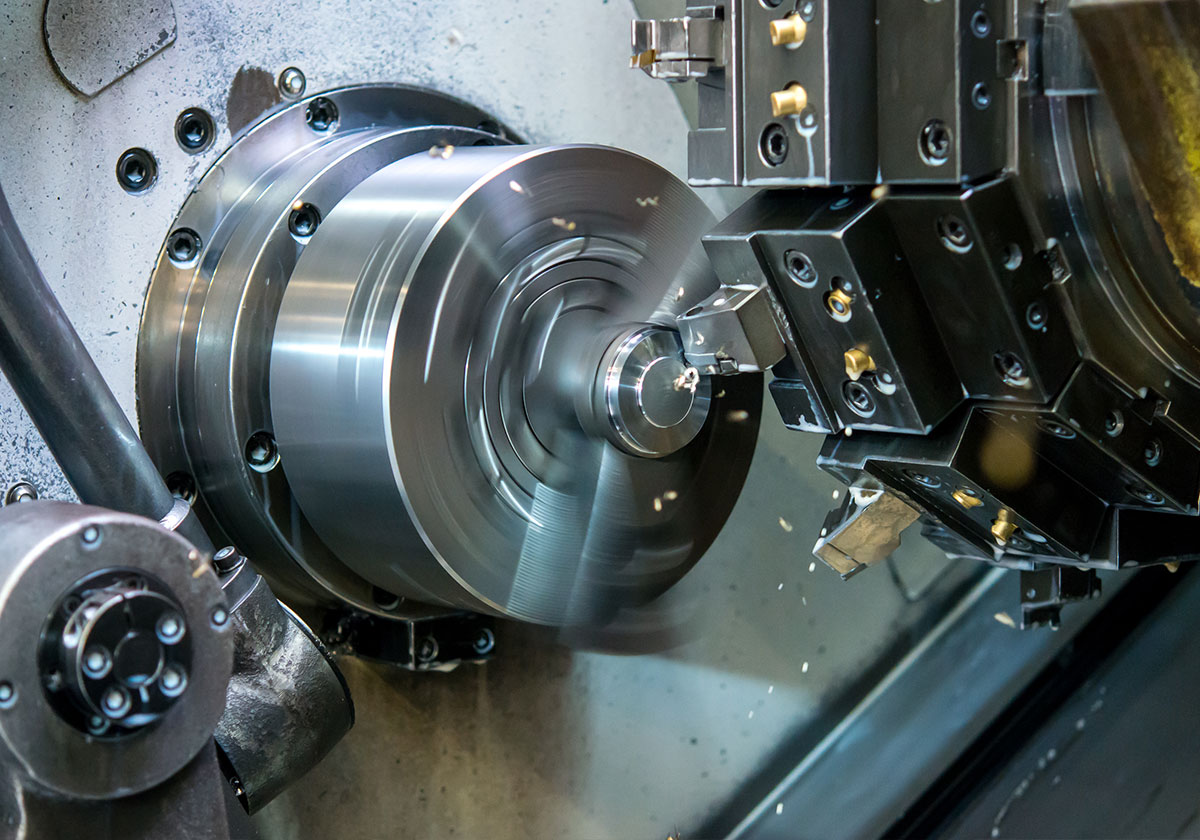

Your partner for CNC machining PROTEAM, s.r.o.

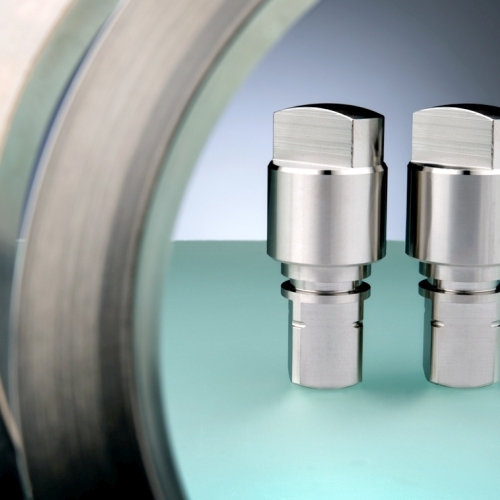

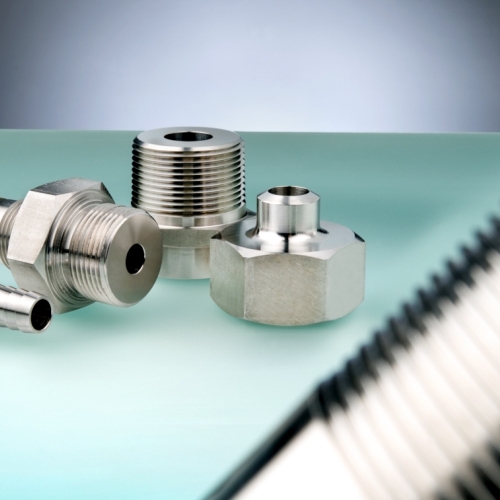

Our company was established in 2006 as a consequence of disintegration of large engineering companies and formation of the space created for development of small, technologically well-equipped companies, that were able to produce new types of products with high technological difficulty and required quality in short time. We are engaged in the production of custom made complex mechanical parts for structural steel, anticorrosive and non-ferrous metals.

We offer following services:

- CNC machining (piece production and medium-sized production)

- Glass bead blasting and beading of metal surfaces

- Dividing of material by sawing to the average of 300 mm

- Transport of finished products up to 1,5 tons

- Washing and preserving of products

- Engineering consultancy

TECHNOLOGY

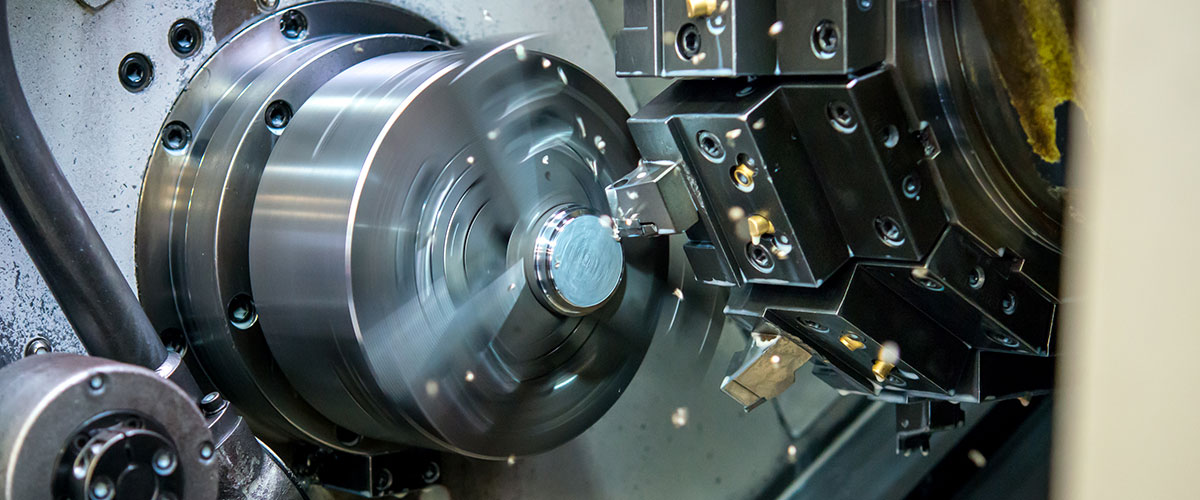

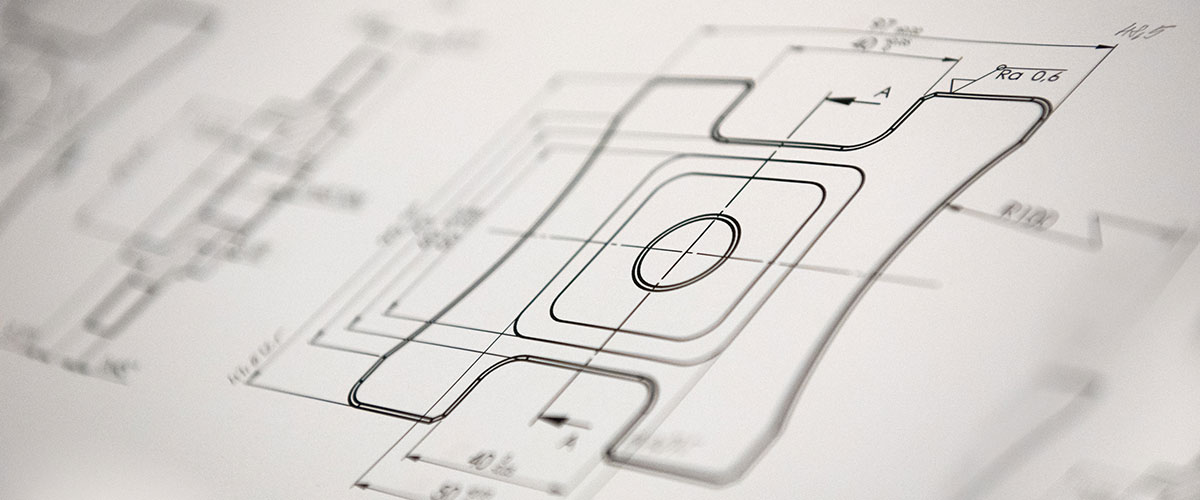

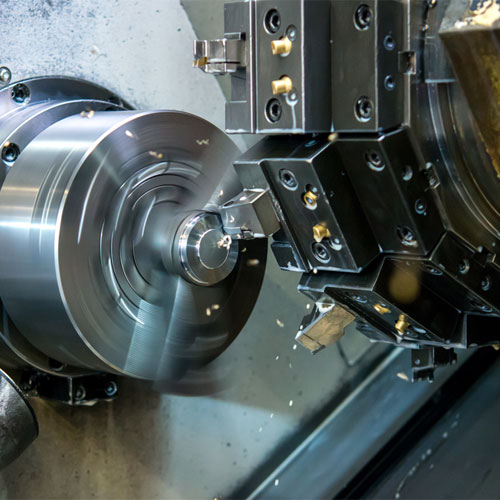

The chip machining of the metals is a part of the production process with which we produce the parts from semi-product and we take off in a propriate way the material in the form of chips. We perform the machining, turning and miling for the chip machining of the metals. We process the colour metals alluminium, bronze, anticorrosive metals and steel on CNC-machines. CNC-machining and milling of the wide pallet of the metals: alluminium, copper, brass, anticorrosive materials, bronze and stainless steel. We offer more axes machining on CNC-machines of 2, 3, 4 and 5 axes. We use the sand blasting with balotine for the surface cleaning and roughening. The metallurgical material dividing with cutting with band saw on demand. For the customers we use CNC-turning of various metals for example alluminium, stainless steel, steel.

2 pcs. CNC - turning machine GOODWAY GA 2600

- Hole through draw tube up to Ø 65 mm

- Spindle speed ranges 40 - 4000 /min

- Motor output ( Cont. ) 11 kW, Motor output ( 30 min.) 15 kW

- Standard CNC control - Oi-TC Fanuc – quick process, any zero point

- Pin clamping

- Max. turning diameter D=280 mm

2 pcs. CMC- turning machine GOODWAY GLS 150

- Hole through draw tube up to Ø 43 mm

- Spindle speed ranges 40 - 6000 /min

- Motor output ( Cont. ) 7,5 kW, Motor output ( 30 min.) 11 kW

- Standard CNC control Oi-TC Fanuc – quick process, any zero point

- Max. turning diameter D=400 mm

- Pin clamping

1 pc. CNC – turning machine GOODWAY GLS 200

- Hole through draw tube up to Ø 51 mm

- Spindle speed ranges 40 - 6000 /min

- Motor output ( Cont. ) 7,5 kW, Motor output ( 30 min.) 11 kW

- Standard CNC control Oi-TC Fanuc – quick process, any zero point

- Max. turning diameter D=420 mm

- Pin clamping

1 pc. CNC – turning machine DOOSAN LYNX 220B

- Hole through draw tube up to Ø 55 mm

- Spindle speed ranges 40 - 6000 /min

- Motor output ( Cont. ) 7,5 kW, Motor output ( 30 min.) 11 kW

- Standard CNC control - Oi-TC Fanuc – quick process, any zero point

- Max. turning diameter D=280 mm

- Pin clamping

1 pc. CNC – turning and milling machine DOOSAN TT1500SY

- Hole through draw tube up to Ø 55 mm

- Spindle speed ranges 40 - 6000 /min

- Motor output ( Cont. ) 11 kW, Motor output (30 min.) 17,5 kW

- Standard CNC control - 18i-TC Fanuc – quick process, any zero point

- Max. turning diameter D=280 mm

- Pin clamping

1 pc. CNC turning and milling machine DOOSAN 2000Y

- Hole through draw tube up to Ø 65 mm

- Spindle speed ranges 40 - 5000 /min

- Motor output ( Cont. ) 17 kW, Motor output ( 30 min.) 22,5 kW

- Standard CNC control - 18i-TC Fanuc – quick process, any zero point

- Max. turning diameter D=280 mm

- Pin clamping

1 pc. CNC turning and milling machine DOOSAN 2100MS

- Hole through draw tube up to Ø 65 mm

- Spindle speed ranges 40 - 5000 /min

- Motor output ( Cont. ) 11 kW, Motor output ( 30 min.) 15 kW

- Standard CNC control - 18i-TC Fanuc – quick process, any zero point

- Max. turning diameter D=406 mm

- Pin clamping

2 pcs. CNC turning and milling machine DOOSAN 2100Y

- Hole through draw tube up to Ø 76 mm

- Spindle speed ranges 30 - 5000 /min

- Motor output ( Cont. ) 11 kW, Motor output ( 30 min.) 18,5 kW

- Standard CNC control - 18i-TC Fanuc – quick process, any zero point

- Pin clamping

2 pcs. CNC machine DOOSAN LYNX 220A

- Hole through draw tube up to Ø 53 mm

- Spindle speed ranges 60 - 6000 /min

- Motor output ( Cont. ) 11 kW, Motor output (30 min.) 15 kW

- Standard CNC control - Oi-TC Fanuc – quick process, any zero point

- Max. turning diameter D=280 mm

- Pin clamping

1 pc. CNC machine DOOSAN LYNX 220LSCY

- Hole through draw tube up to Ø 76 mm

- Spindle speed ranges 60 - 4500 /min

- Motor output ( Cont. ) 11 kW, Motor output (30 min.) 15 kW

- Standard CNC control - Oi-TC Fanuc – quick process, any zero point

- Max. turning diameter D=280 mm

- Pin clamping

2 pcs. Band saw automatic machine Pegas 235

- Cutting of round material up to diameter of 230 mm

- Cutting of rectangular material up to a size of 300x210mm

- Possibility to cut of material up to angle of +/- 60 degrees

Hydraulic two-column automatic belt saw WA 4033-HA

- Cutting range „O“ profile 20 – 330 mm

- Square profile 400 x 330 mm

- Belt speed: 20 – 90 m/min

- Weight of the saw: 2 300 kg

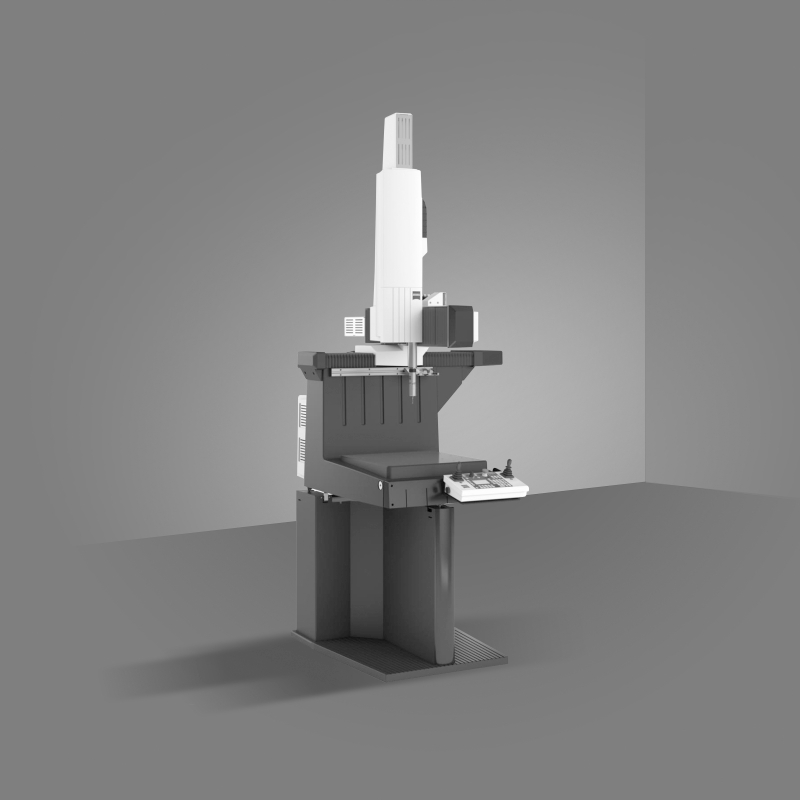

3D Measuring Machine DuraMax 500 x 500 x 500

- VAST XXT TL 3 Scanning Sensor

- Reference Standard, calibre 25 mm

- Contour Detector (measuring range Z = 60 mm)

- Detector Hybrid (measuring range Z = 10 mm)

- Abrasiveness Detector

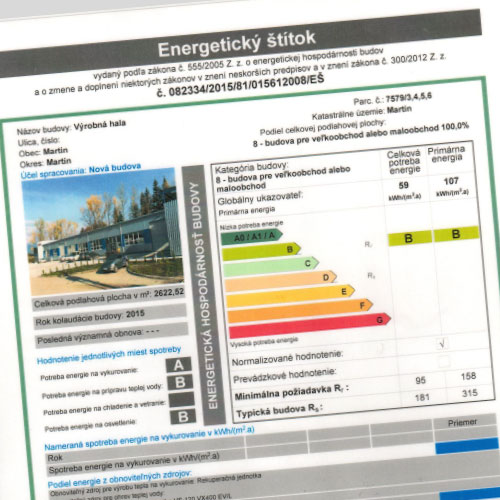

PROJECTS IMPLEMENTED WITH EU SUPPORT

OUR REFERENCES

CONTACT

PROTEAM, s.r.o.

Headquarters: Flámska 11198, 036 01 Martin, Slovakia

Tel.: +421 43 5864 757

Contact E-mail: proteam@proteamsro.sk

Billing information:

Business ID: 36359998

Tax ID: 2022190456

VAT no.: SK2022190456

Registered in the Commercial Register of the District Court of Žilina Section Sro, Insert 17548 / L

Banking information:

ČSOB, a.s.

IBAN: SK72 7500 0000 0040 0365 4059

SWIFT: CEKOSKBX

VÚB, a.s.

IBAN: SK05 0200 0000 0033 5089 0756

SWIFT: SUBASKBX

Company Management:

Zuzana Janečková

Executive Manager, Sales Manager

E-mail: janeckova@proteamsro.sk

Miloš Bada

price quotes

E-mail: bada@proteamsro.sk

Commercial and Production Department:

Bc. Simona Horská

Sales Manager

E-mail: horska@proteamsro.sk

Ing. Lenka Farkašová

Sales Manager

E-mail: farkasova@proteamsro.sk

Mgr. Jana Ivanová

Sales Manager

E-mail: ivanova@proteamsro.sk

Mgr. Silvia Miklošová

Production Supervisor

E-mail: miklosova@proteamsro.sk

Quality Control Department:

E-mail: kontrola@proteamsro.sk

Andrea Kvašňovská

Miroslav Adamčík

Andrea Sokolová